- Home

- News & Events

- News

- Resin Selection Guideline for High Power Connectors to Enhance Product Performance and Durability

January 19, 2023

<< Back

Resin Selection Guideline for High Power Connectors to Enhance Product Performance and Durability

In recent years, with the vigorous development of data centers, data centers have higher and higher requirements for efficiency and specifications. Therefore, the selection of materials plays a crucial role in the process of data center upgrades. Resin materials are widely used in high power connectors. They are mainly used to support conductors and provide insulation functions. They can also be used to make various other functional parts, such as housings, buckles, nuts, etc. There are many kinds of resin materials with different performances. It is crucial to choose the appropriate resin material according to the different application environments and functional requirements of the connector. The main characteristics of resin materials are mechanical properties, electrical properties, heat resistance, flame retardancy, etc. Mechanical properties include Tensile Strength, Flexural Strength, Impact Strength, and Hardness. Electrical properties include Volume Resistivity, and Comparative Tracking Index (CTI). Heat resistance includes Heat deflection temperature and Relative Thermal Index (RTI). Flame retardancy, based on the UL94 rating, can be classified into HB、V-2、V-1、V-0、5VA、5VB. Based on actual product development experience, this article shares the considerations for selecting resin materials for the following types of connectors. Based on its rich and professional product development experience, BizLink has established its professional knowledge and development process for selecting different resin materials for different application environments and industrial needs.

High Current Connectors for Data Centers

We have entered the big data society with rapid development of cloud computing. The massive data computing capability of cloud servers is inseparable from a sufficient power supply, and the use of high-current connectors in data centers is becoming more and more important. Unlike photovoltaic connectors that have been used outdoors, high-current connectors used in data centers are used in relatively mild environments. They are generally used indoors with air conditioning and do not require high waterproof performance or UV resistance. The temperature rise performance is the first consideration for this type of connector, and the upper limit temperature of the temperature rise test cannot be higher than the RTI value of the resin material, so it is necessary to choose a resin material with a higher RTI value. Considering fire safety, it is recommended to choose V0 or above for the fire rating of resin materials. In addition, the resin material also needs to have good impact resistance to pass the drop test. The CTI value of the resin material affects the creepage distance of the product, and the resin material with a suitable CTI value should be selected according to the product voltage and the actual structure of the product.

Figure 1. BizLink 747-H3 connector

Immersion cooling

As the computing power of the data center increases, the heat generation climbs accordingly. For better heat dissipation, more and more data centers adopt the immersion liquid cooling design, immersing the entire server in a dedicated cooling liquid. For connectors used in immersion cooling, due to long-term immersion in cooling liquid, it is necessary to consider the corrosion of the cooling liquid on the resin material, the impact on the physical properties of the resin material, and whether the resin material itself will precipitate and pollute the cooling liquid. To confirm whether the resin material is suitable for immersion cooling, we need to put the resin material into the cooling liquid for the immersion test, comparing the changes in the physical properties such as changes in tensile strength, bending strength, etc. Changes in composition of the resin material and of the cooling liquid before and after the test are put into consideration as well.

Solar / Photovoltaic Connectors

Facing the intensification of the global energy crisis and the increasing environmental pollution generated by the combustion of traditional energy sources, solar photovoltaic power generation has become one of the important new energy sources. Photovoltaic solar energy is obtained by converting sunlight received through solar panels into electricity, exporting it through wires and connectors. Multiple solar panels are connected in series/parallel through connectors to achieve the voltage and current designed for the power generation system. Since the installation of solar panels is exposed to the outdoors for a long time, many power stations are directly built in harsh environments such as Gobi and deserts. The photovoltaic connectors are for outdoor application as well with generally 10-20 year design life. High-level requirements are needed to achieve waterproof performance, high/low temperature resistance and UV resistance.

Solar / Photovoltaic Connectors

Facing the intensification of the global energy crisis and the increasing environmental pollution generated by the combustion of traditional energy sources, solar photovoltaic power generation has become one of the important new energy sources. Photovoltaic solar energy is obtained by converting sunlight received through solar panels into electricity, exporting it through wires and connectors. Multiple solar panels are connected in series/parallel through connectors to achieve the voltage and current designed for the power generation system. Since the installation of solar panels is exposed to the outdoors for a long time, many power stations are directly built in harsh environments such as Gobi and deserts. The photovoltaic connectors are for outdoor application as well with generally 10-20 year design life. High-level requirements are needed to achieve waterproof performance, high/low temperature resistance and UV resistance.

Figure 2. Photovoltaic power station

Typical parameters of general photovoltaic connectors are as follows:

Rated voltage: DC 1000V to 1500V,

Rated current: from 15A to 90A,

Ambient temperature: -40℃~+85℃,

Protection level: the minimum reaches IP67 level.

Rated voltage: DC 1000V to 1500V,

Rated current: from 15A to 90A,

Ambient temperature: -40℃~+85℃,

Protection level: the minimum reaches IP67 level.

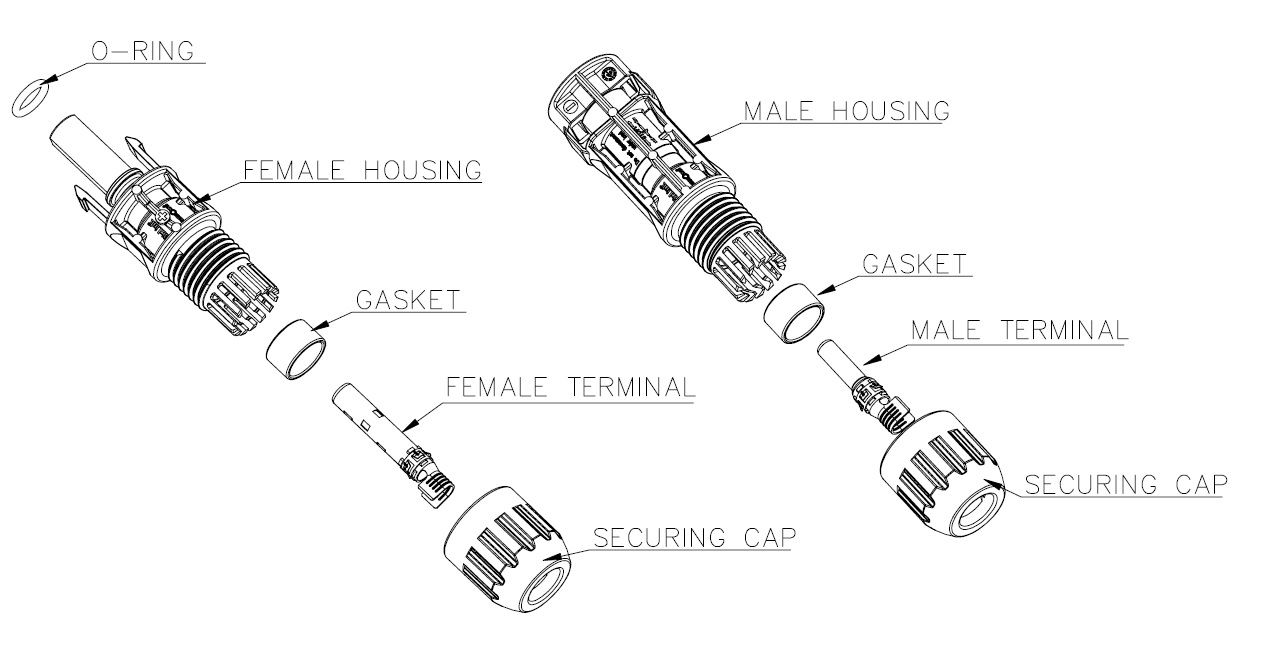

The typical structure of a photovoltaic connector includes a male connector and a female connector composed of a male body, a male terminal, a female body, a female terminal, a waterproof ring, a nut, screw caps using resin materials, and other components.

Figure 3. photovoltaic connector structure

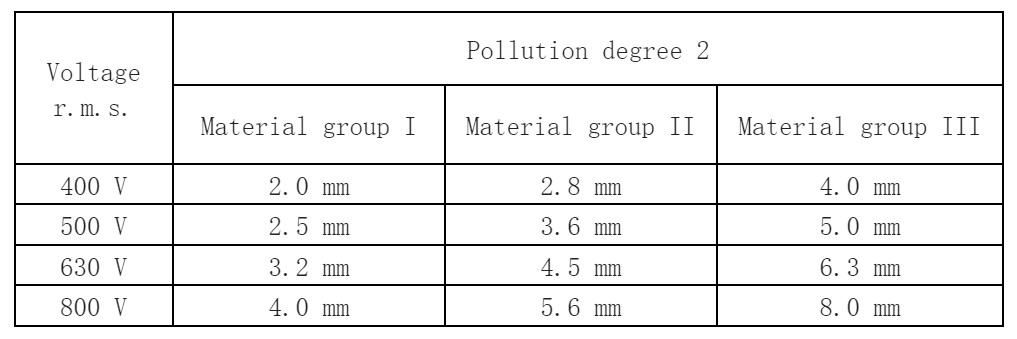

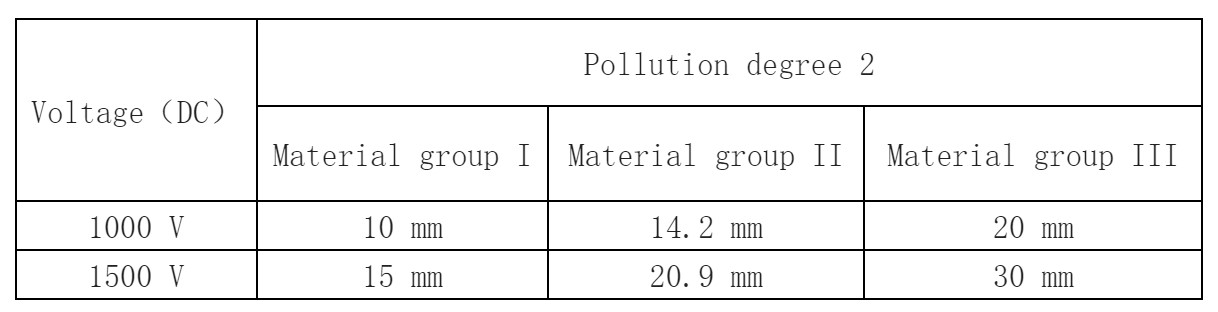

For resin materials used outdoors, both UV resistance and hydrolysisresistance are indispensable. According to the requirements of photovoltaic connector safety standards, the resin material of the shell must pass the ultraviolet exposure test (Ultraviolet light exposure) and water immersion test specified in the UL746C standard (Water exposure and immersion). When the resin material itself undergoes UL certification, after passing this test, the suffix (f1) will be added after the model number. In consideration of fire safety, the resin material of the casing must meet the V-0 or 5VA heat resistance level specified in the UL94 standard. Relative Thermal Index (RTI) refers to the ability of a material to maintain specific properties (physical, electrical, etc.) when exposed to high temperatures for a long time. Considering the ambient temperature of the photovoltaic connector, the RTI should be greater than or equal to 105°C. The above fire rating and RTI value are related to the minimum thickness of the material, so they should be determined according to the minimum thickness of the actual product structure. Relative tracking index (Comparative Tracking Index, referred to as CTI) is the susceptibility of trace materials to track. These parameters of CTI are very important, but they are often easily ignored when it comes to material selection. According to the IEC standard, materials are divided into the following four groups of the CTI values.

Material Group I: CTI ≥600

Material Group II: 400 ≤ CTI < 600

Material Group IIIa: 175 ≤ CTI < 400

Material Group IIIb: 100 ≤ CTI < 175

Material Group II: 400 ≤ CTI < 600

Material Group IIIa: 175 ≤ CTI < 400

Material Group IIIb: 100 ≤ CTI < 175

The creepage distance corresponding to different CTI materials is shown in the table below. According to the limitation of the structure of the product itself, generally speaking, photovoltaic connectors should choose materials with CTI ≥ 400 to meet the requirements of creepage distance.

In addition, we have to put hail impact into consideration for outdoor application, so the material must have good low temperature impact resistance. Specifically, the product is required to withstand an impulse of 6.78J at -35°C. Materials suitable currently are PPE/PPO, PC, and PA materials.

Each connector has its own application environment, such as indoors, outdoors, air and coolant. How to select the most appropriate material according to the application environment and functional requirements to maximize the efficiency of use and maintain stable and excellent quality is BizLink's consistent commitment.

Each connector has its own application environment, such as indoors, outdoors, air and coolant. How to select the most appropriate material according to the application environment and functional requirements to maximize the efficiency of use and maintain stable and excellent quality is BizLink's consistent commitment.