- トップページ

- ニュース & イベント

- ニュース

- Drive high-performance power and communication connections for EV/HEV applications

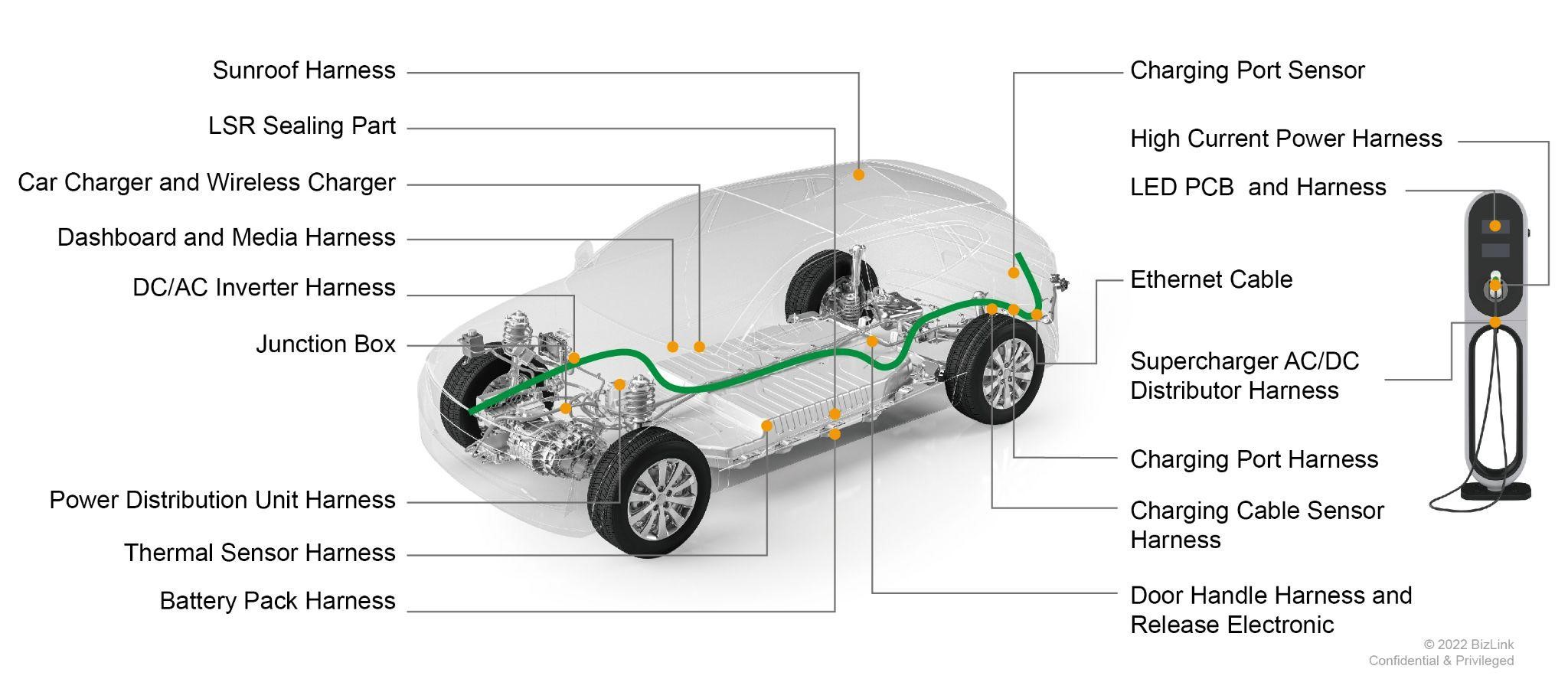

Globally recognized as a trusted supplier with more than 25 years of expertise in developing proven, reliable interconnect solutions for a wide range of cross-market industries, BizLink delivers an extensive portfolio of power and communication electronic interfaces for EV and HEV applications. The company’s product offerings include high voltage harnesses, low voltage harnesses, wireless chargers, charging port harnesses, battery pack harnesses, and Ethernet cables. Supporting BizLink’s high-power, high-performance electronics are the company’s advanced ODM and OEM capabilities, which include cutting-edge design manufacturing processes, state-of-the-art facilities, and a team of highly skilled professionals with experience in research and development.

ODM Capabilities

For the design of innovative interconnect solutions, BizLink relies on its distinguished multi-disciplinary Research and Development (R&D) team. Composed of engineering and service professionals with extensive experience collaborating with the most sought-after EV/HEV manufacturers, this specialized team provides comprehensive, systematic oversight involving all areas of design, ranging from vehicle-level knowledge and experience to the most intricate component-level details. Employing a multi-physics integration approach to enable optimal design, BizLink’s highly skilled R&D team develops products that: have RF high frequency and high voltage capabilities, exhibit reliable thermal and mechanical characteristics, are user friendly (i.e., customized enclosures), utilize advanced software technology, and adhere to the most stringent safety standards.

BizLink ensures the manufacturing of high-quality products by adopting a hardware and software development model that mirrors a “V-shape” to ensure that each step in the process is followed by rigorous testing before moving on to the next phase. For example, BizLink's EV chargers feature a compact, modularized, and portable design to fit various grid and EV interfaces. Manufactured using the V-model process, these devices offer charging management systems with a connected charging spot, and have enabled BizLink to evolve from defining its own manufacturing requirements to being able to mass produce IEEE-compliant products that meet international automotive quality standards, including IATF 16949, CMMI, and ISO26262, as well as UL, IEC, and ISO safety standards, in their own facilities. As such, BizLink has developed a comprehensive standard-certified portfolio of products that support power and communication networks for the EV/HEV industry.

OEM Capabilities

As a leading global OEM, BizLink has the capability to offer full-scale manufacturing ranging from individual, specific component parts to fully integrated electronic devices. To produce this comprehensive range of design solutions, BizLink employs several different manufacturing processes, including cable and connector manufacturing lines, PCB assembly lines, and final product assembly lines – all which are IATF-16969 certified.Like the company’s R&D team, BizLink sales professionals also have extensive experience working with leading EV companies relating to OEM services, such as product quotations, MFA, prototyping, manufacturing and production, and quality control. This experience, coupled with BizLink’s ability to streamline large-scale development projects, enable BizLink to provide customers with design-for-manufacturing services that not only enhance the quality of original designs, but also contribute to more cost effective, quicker-to-market delivery by partnering with smaller, local companies.

Power Electronics for EV and HEV

Unlike competitors who only offer discrete, individual parts, BizLink takes pride in providing customers with a total power electronics solution for their EV and HEV applications. For this reason, the company has developed a comprehensive Vehicle Power Network, which is made up of electrical lines connecting the vehicle to the electric grid, as well as lines that bi-directionally connect EV batteries to the actuator, sensors, and other devices.Vehicle-to-Grid

Consisting of compact high-capacitance EV battery chargers and a system of high voltage connectors and cables, this capability allows batteries to deliver safe, quick charging to EVs, while also returning power to the electrical grid by acting as an alternate source of power.

In-Vehicle

This refers to an internal automotive system of high voltage connectors and cables that connect batteries and devices, including DC/DC converters, high and low voltage batteries, AC converters, and AC compressors.

Vehicle to Driver and Passengers

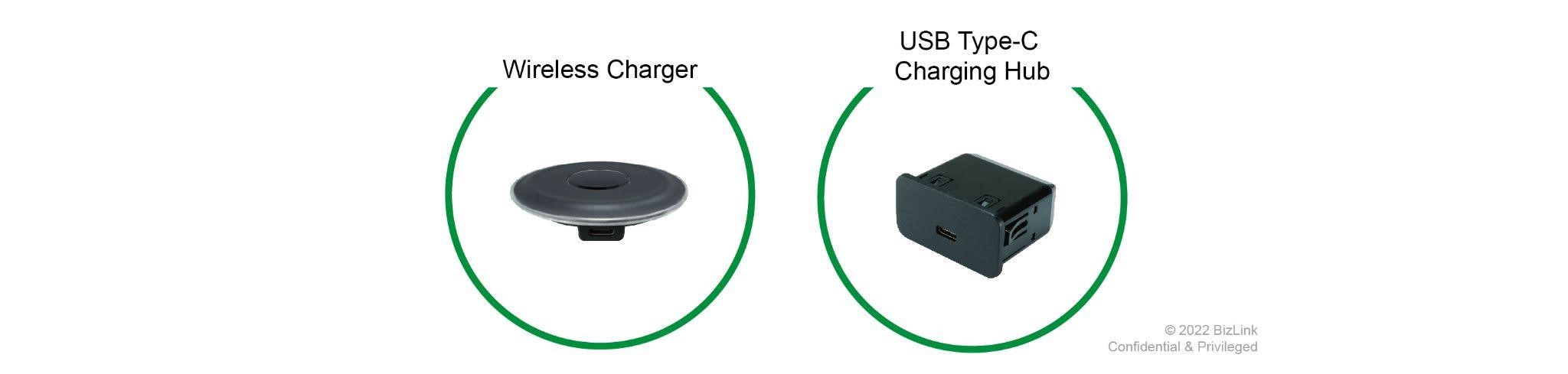

Ranging from WPC-Qi wireless chargers to compact Type-C USB chargers, these interfaces allow for the charging of personal electronic devices while driving/riding in EVs. BizLink’s chargers meet the specifications for Qi chargers and feature a core wireless module with a customized housing for seamless assembly.

Communications Electronics for EV/HEV

Similar to its Vehicle Power Network, BizLink also offers customers a total communication electronics solution for their EV and HEV applications. The company’s Vehicle Communication Network is an extensive system that connects in-vehicle devices with charging management platforms for communicating and exchanging data. To accomplish this, the system utilizes both low-speed controller area network (CAN) bus and high-speed automotive Ethernet protocols.Controller Area Network (CAN)

Consisting of a low-speed bus system (i.e., cables, connectors, and controllers), CAN is ideally suited for use in the harness of cameras for Advanced Driver Assistance Systems (ADAS), DC/DC, and AC control. In compliance with ISO standards, the CAN Bus protocol also meets the requirements for verified software with makers of lighting for EVs.

Ethernet

Ranging from 100Mbps to 1Gbps, high-speed Ethernet networks are composed of IEEE-standard 802.3 compatible cables, connectors, and controllers, and feature electromagnetic (EM) simulation for optimum cable and connector design. Additionally, BizLink’s Ethernet option allows for in-house fixture development to assess transmission performance throughout operation.

.jpg)

BizLink continuously strives to advance its ODM/OEM interface capabilities and to develop innovative, high-performance interconnect solutions and technologies that meet the industry’s growing demands. For more information, visit BizLink’s website.