- Startseite

- Neuigkeiten & Ereignisse

- Nachrichten

- A Look at What's Driving Everyday Appliances

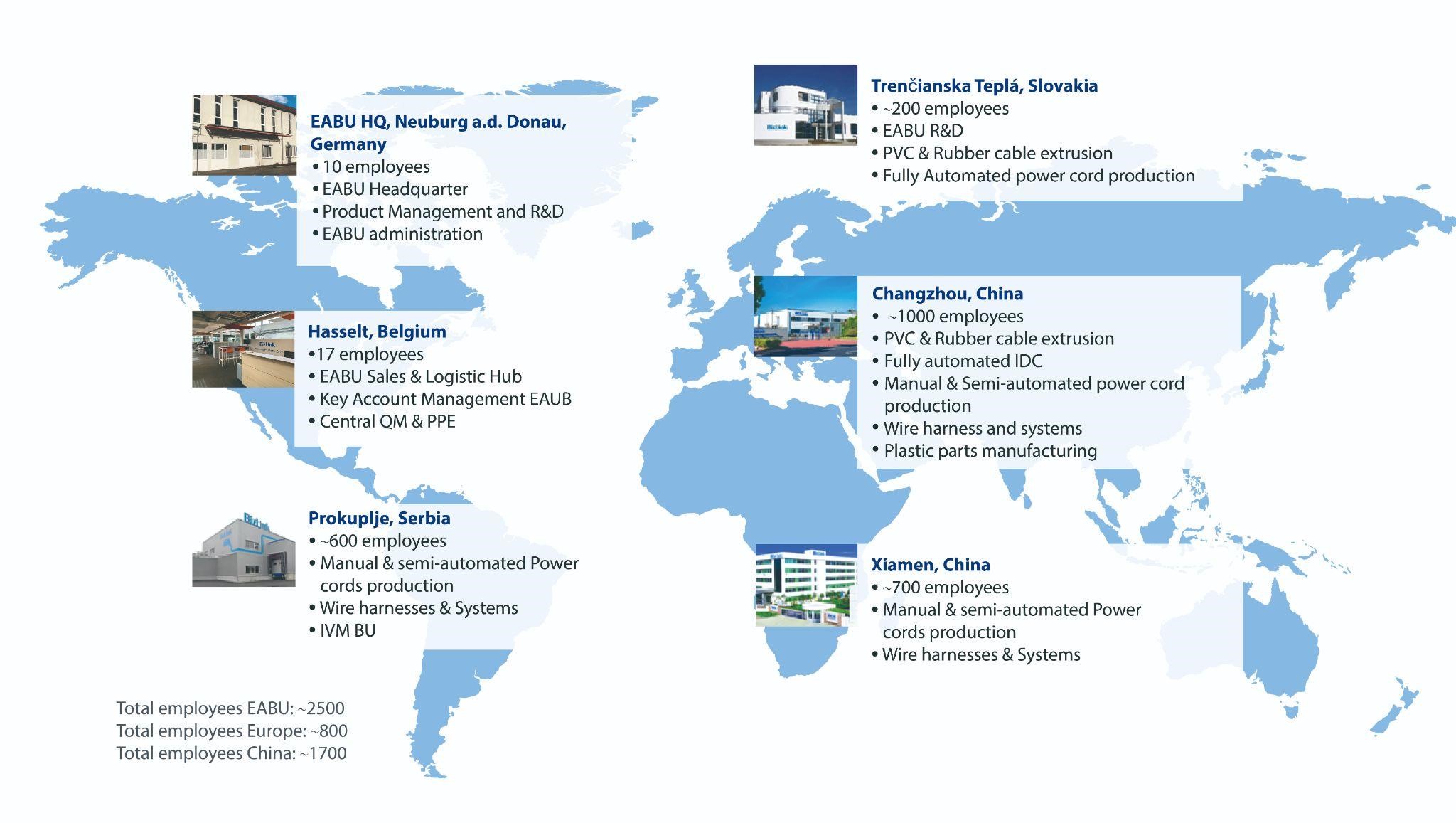

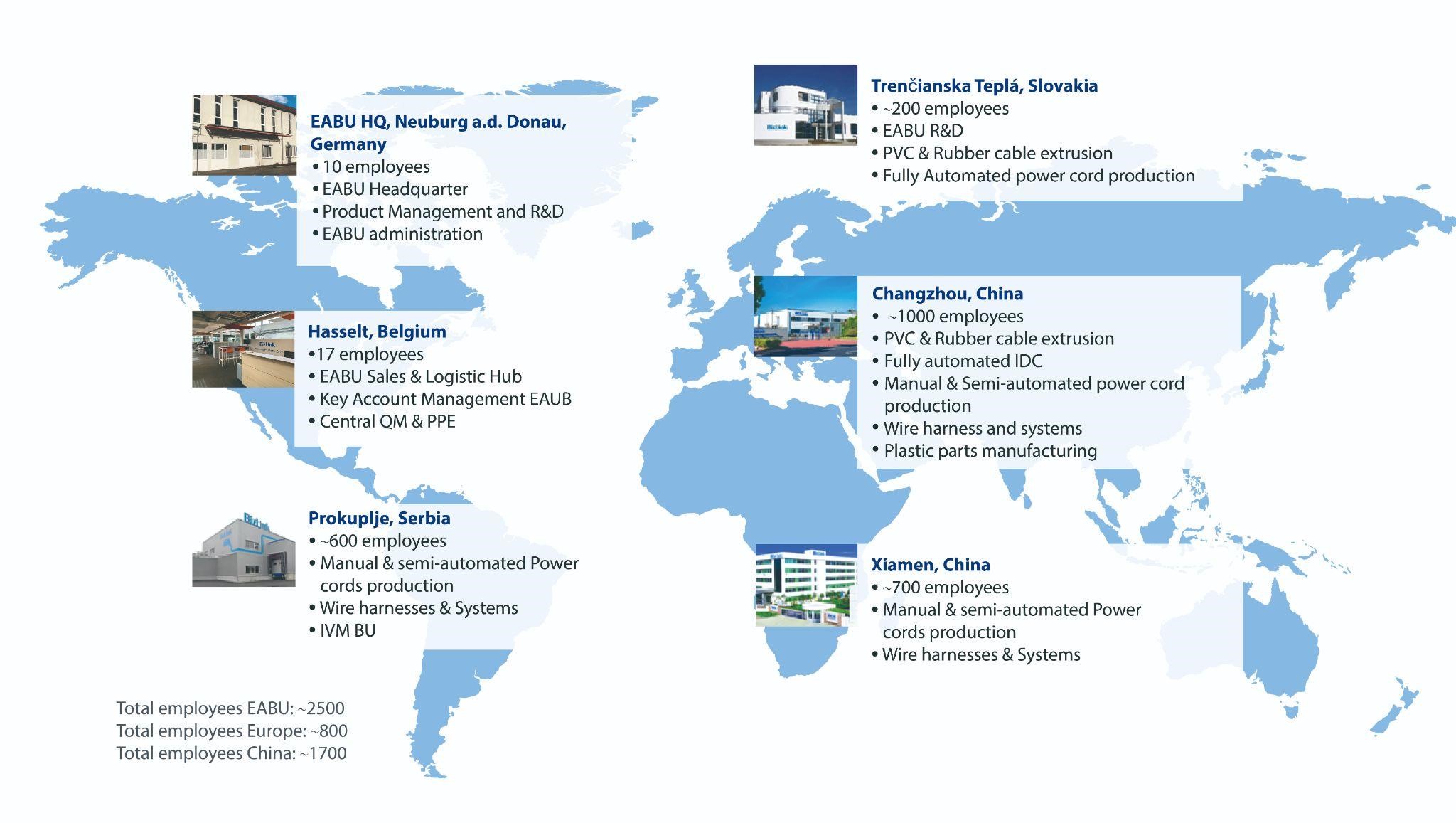

Without a doubt, electronics are an essential part of our everyday lives. From the moment we wake up in the morning to the time we fall asleep at night, technology is working for us and helping to simplify our day-to-day tasks. While some of the ways are more commonly noticeable, like making a phone call or using the computer, there are other instances in which the value of electronics may not be as obvious, such as eating breakfast or having a cup of coffee. Regardless, the integration of electronics and technology into our lives has revolutionized the ways in which we get things done and interact with each other. At BizLink, one of the leading cable assembly manufacturers worldwide, we pride ourselves in developing a wide range of innovative cables, connectors, and wiring solutions that help to power the appliances (i.e., coffee makers, washing machines, refrigerators, etc.) and other products (i.e., electrical toothbrushes, power drills, alarm clocks, etc.) that make our lives easier. This white paper will discuss BizLink’s extensive electrical interconnect portfolio, which spans internal wiring, plugs, connectors, bulk cables, as well as systems and customized products, and will explain how these products are specifically designed using the highest-quality materials, and rigorously tested to ensure that they meet the highest regulatory and environmental standards throughout the globe.

Internal Wiring

With production facilities in Slovakia, Serbia, and China, BizLink supplies the key players within the electrical appliance industry with internal wiring through the development and production of our ready-to-fit cable harnesses and connecting cables. These products are ideal for use in common household appliances such as white goods, irons, coffee makers, vacuum cleaners, and multi-functional kitchen appliances. Other uses for these cable sets and wiring include solariums, electric lawn mowers, central heating units, professional IT equipment, as well as personal and healthcare appliances.

.png)

All of BizLink’s internal wiring is manually assembled, partially undergoing fully automated IDC production processes at our state-of-the-art facilities in Asia and Europe (Figure 1). Examples of these processes include:

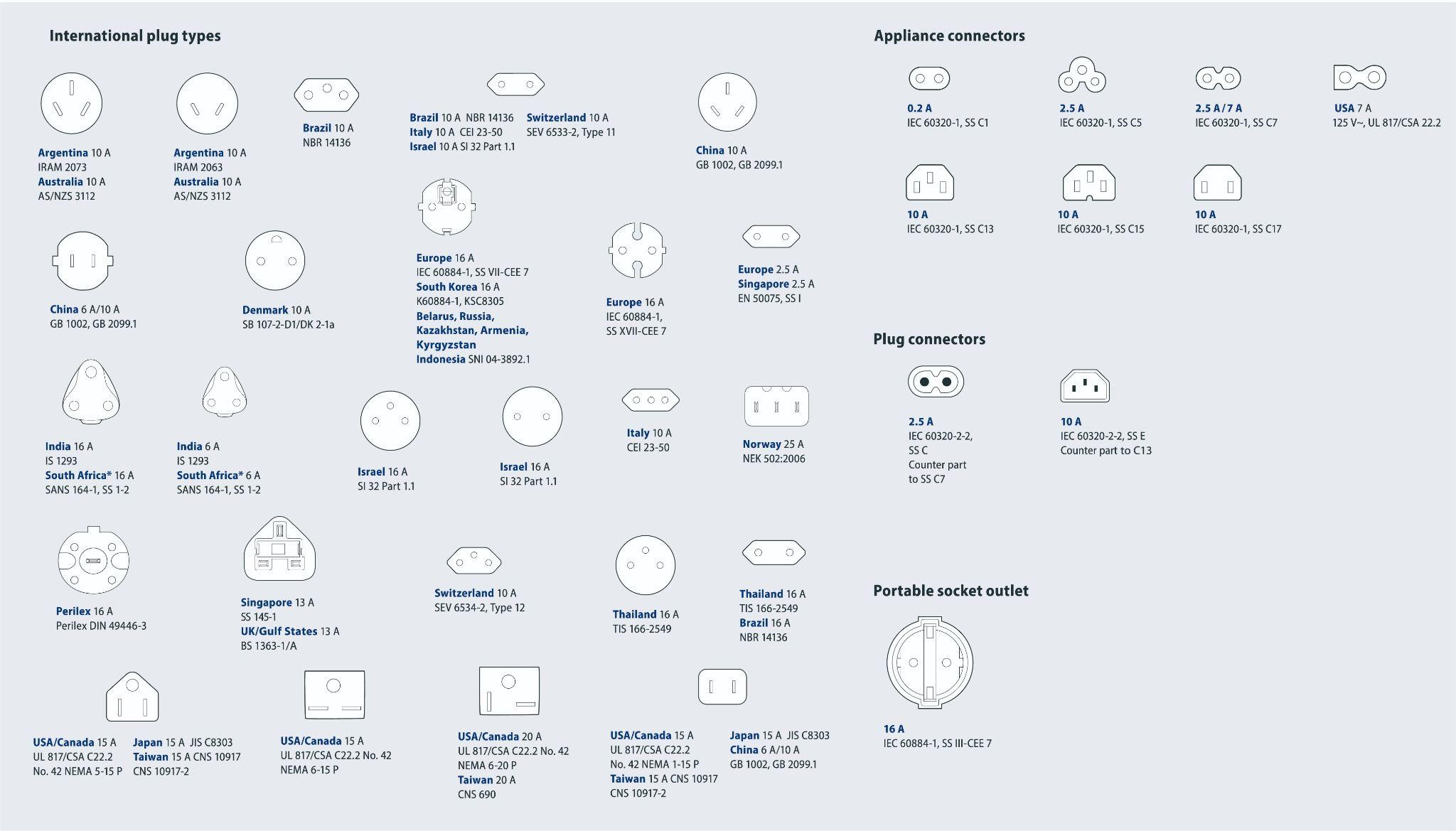

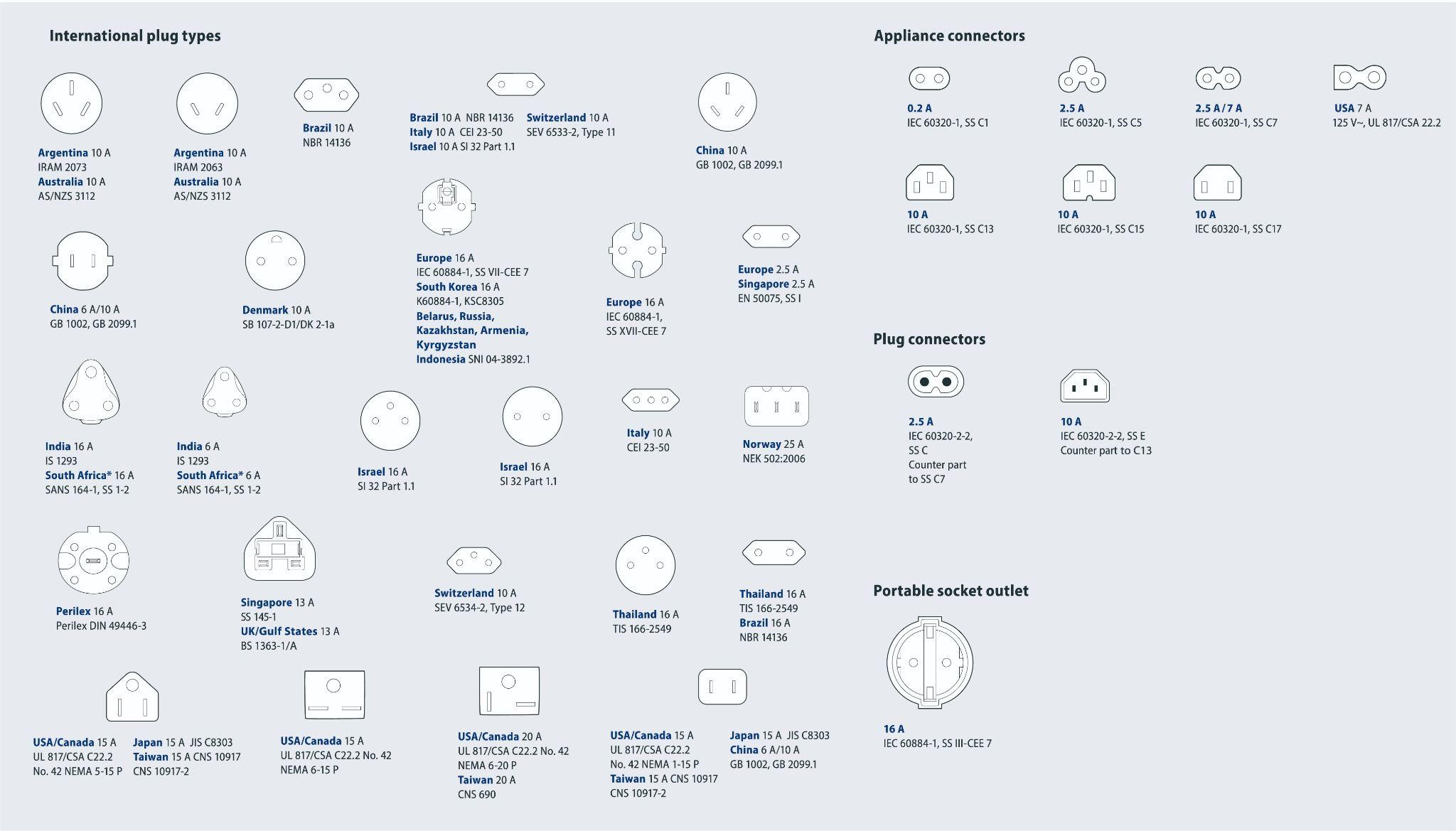

At BizLink, we offer a unique range of plugs and connectors that are designed to meet the vastly different electrical power requirements of countries throughout the world (Figure 2). Our extensive range of interconnect solutions include two-, three-, and four-pole plugs, angled- and straight-shaped plugs, contour and flat plugs, connectors, as well as fully customized specific-assembly parts based on customers' needs.

.png)

All our appliance connectors, plug connectors, and plug socket outlets are designed and specified according to the maximum electric current required, which can range from 0.2A up to 16A (Figure 3). In addition, each of BizLink's plugs and connectors are approved for use with a wide range of various cables, including PVC, high-temperature PVC, textiles, polyurethane cables, and different rubber materials, such as RR, RN, BB, RN8, and more. Our portfolio also includes halogen-free materials for plugs and connectors.

Bulk Cables

At BizLink, we manufacture both standard and customized halogen-free bulk cable solutions, according to the most stringent, high-quality standards of UL, Japan, and other approval bodies. Our bulk cables meet the requirements of PVC-insulated wires and cables, as well as those that are cold- and heat-resistant up to 105°C.

In addition to standard and customized cables, we also offer polyurethane cables and submersible rubber cables – all of which can be used in dry, humid, cold, or wet environments. Our textile braided cables provide ideal solutions for applications such as electric irons, steam generator irons, and electric lighting.

Systems and Customized Solutions

Unlike other competitors, BizLink’s unique engineering capabilities allow the company to work closely and collaboratively with customers to develop customized, innovative solutions that are designed to meet their specific challenges while adhering to the highest standards. Some examples of our most advanced product solutions include:

Additionally, the company offers ample solutions for applications such as wireless charging, which is often utilized in appliances like power tools. To support the increased efficiency and enhanced performance of its systems products, BizLink has extended its assembly capabilities to include “full assembly” and “subassemblies.” For example, the company’s charger units feature molded parts for housing or visual components.

BizLink has proven expertise in material handling to ensure the highest reliability and durability of its products. The company’s R&D activities are performed in-house and with third-party laboratories, as well as with educational institutions, resulting in a broad portfolio of proven, stringently tested cable types based on multiple material groups.

Each of BizLink’s cable, connector, and wiring solutions are developed using either thermoplastic materials, which are available as plasticized PVC or halogen free; thermoplastic elastomers (TPO / TPE / TPV); or elastomer materials, which consists of vulcanized rubber including NBR / EPDM / CPE.

Whichever material listed above is used, all of them are subject to regular quality control, and are developed and tested according to customer specifications, and national and/or international standards. These materials also offer optimal flexibility to meet new or modified requirements.

All of BizLink’s carefully selected and tested materials share common characteristics including:

BizLink adheres to strict quality control checks that are performed at all stages in the production process. In addition, the company’s entire range of products are ISO 9001:2015 and ISO 14001:2015 approved, and are 100 percent electrically tested for functional and safety-related parameters, and comply with all applicable national and international standards.

BizLink's vast product portfolio of plugs, connectors, and bulk cables are approved by a wide range of National Certification Bodies (NCB) from around the world, including Australia, Japan, and the U.S.A. We also supply plugs for countries in which NCB-approval is not mandatory (Figure 4).

With the growing push in several countries to ban phthalates and PAHs as they relate to the framework of RoHS II and similar approaches, BizLink has prioritized creating clean, sustainable products that reduce the risk of environmental impact. As a result of this initiative, the company has developed a range of halogen-free products, which do not contain halogens – chlorine (CI), bromine (Br), fluorine (F), iodine (I), and astatine (At), and have characteristics that are similar to PVC.

In compliance with EN 50525-3-11 standards, these halogen-free cable products deliver several benefits and key features including:

Internal Wiring

With production facilities in Slovakia, Serbia, and China, BizLink supplies the key players within the electrical appliance industry with internal wiring through the development and production of our ready-to-fit cable harnesses and connecting cables. These products are ideal for use in common household appliances such as white goods, irons, coffee makers, vacuum cleaners, and multi-functional kitchen appliances. Other uses for these cable sets and wiring include solariums, electric lawn mowers, central heating units, professional IT equipment, as well as personal and healthcare appliances.

.png)

All of BizLink’s internal wiring is manually assembled, partially undergoing fully automated IDC production processes at our state-of-the-art facilities in Asia and Europe (Figure 1). Examples of these processes include:

Plugs and Connectors

- IDC Technology – Also known as insulation-displacement connector technology, this is used when a connector is specifically designed to connect to the insulated wire’s conductor. During this process, the connector blade cold-welds to the wire, enabling a highly reliable gas-tight connection while reducing the likelihood of any mating and plugging errors. Proven results show improvements in quality performance with significant failure rate (ppm) reductions.

- Ultrasonic Welding – The latest technology for connecting multiple wires with one another, ultrasonic welding allows for up to eight wires, measuring no more than 20mm2 in total cross-section, to be welded together.

- Resistance Welding – This automated process is used when connecting wires to each other or to metal parts or surfaces. Additional resistance welding is also performed on crimped connections.

At BizLink, we offer a unique range of plugs and connectors that are designed to meet the vastly different electrical power requirements of countries throughout the world (Figure 2). Our extensive range of interconnect solutions include two-, three-, and four-pole plugs, angled- and straight-shaped plugs, contour and flat plugs, connectors, as well as fully customized specific-assembly parts based on customers' needs.

.png)

All our appliance connectors, plug connectors, and plug socket outlets are designed and specified according to the maximum electric current required, which can range from 0.2A up to 16A (Figure 3). In addition, each of BizLink's plugs and connectors are approved for use with a wide range of various cables, including PVC, high-temperature PVC, textiles, polyurethane cables, and different rubber materials, such as RR, RN, BB, RN8, and more. Our portfolio also includes halogen-free materials for plugs and connectors.

Bulk Cables

At BizLink, we manufacture both standard and customized halogen-free bulk cable solutions, according to the most stringent, high-quality standards of UL, Japan, and other approval bodies. Our bulk cables meet the requirements of PVC-insulated wires and cables, as well as those that are cold- and heat-resistant up to 105°C.

In addition to standard and customized cables, we also offer polyurethane cables and submersible rubber cables – all of which can be used in dry, humid, cold, or wet environments. Our textile braided cables provide ideal solutions for applications such as electric irons, steam generator irons, and electric lighting.

Systems and Customized Solutions

Unlike other competitors, BizLink’s unique engineering capabilities allow the company to work closely and collaboratively with customers to develop customized, innovative solutions that are designed to meet their specific challenges while adhering to the highest standards. Some examples of our most advanced product solutions include:

- Multi- and single-layer cordwinders – Developed in-house, these rewind devices are used in vacuum cleaners and steam generators, and are designed to meet customers’ technical specifications regarding heat resistance, low friction, high flexibility, and being halogen-free.

- Integration of electrical and mechanical parts – Incorporate different types of electronics such as sensors, RFI filters or indicating elements (e.g. LED) into power cords or wire harnesses

- Over molding of fixings and mountings for cable harnesses – Cable harnesses fitted with injection molded grommets, fixings, and mounting brackets

- Assembly of plastic parts, housings or fixtures to wire harnesses – Ready-to-install modules delivered to customer

- Connections to PCBs – Connection of wire harnesses or power cords with PCB and testing according to customer specifications

- Customer specific locking systems for connectors, plugs and power cords – Mechanical locking parts for cord sets for connecting the electrical appliance with the power cord. They are detachable for quick exchange or non-detachable.

- Storage Boxes – Designed as a more cost-efficient alternative to cordwinders, cable storage boxes allow for the storage of additional or surplus cable either directly within the appliance or in a separate outside box.

- Steam Tubes – This textile braided system is composed of at least one EPDM or silicone tube made for transporting the steam or water and PVC or rubber-insulated multi-core cable.

- Hose Tubes – This textile braided system provides larger diameters for transporting low pressure steam.

Additionally, the company offers ample solutions for applications such as wireless charging, which is often utilized in appliances like power tools. To support the increased efficiency and enhanced performance of its systems products, BizLink has extended its assembly capabilities to include “full assembly” and “subassemblies.” For example, the company’s charger units feature molded parts for housing or visual components.

Materials

BizLink has proven expertise in material handling to ensure the highest reliability and durability of its products. The company’s R&D activities are performed in-house and with third-party laboratories, as well as with educational institutions, resulting in a broad portfolio of proven, stringently tested cable types based on multiple material groups. Each of BizLink’s cable, connector, and wiring solutions are developed using either thermoplastic materials, which are available as plasticized PVC or halogen free; thermoplastic elastomers (TPO / TPE / TPV); or elastomer materials, which consists of vulcanized rubber including NBR / EPDM / CPE.

Whichever material listed above is used, all of them are subject to regular quality control, and are developed and tested according to customer specifications, and national and/or international standards. These materials also offer optimal flexibility to meet new or modified requirements.

All of BizLink’s carefully selected and tested materials share common characteristics including:

- Flexibility, hardness, and elasticity

- Mechanical stability under load

- Migration resistance

- Retention of physical and mechanical properties before and after aging

Testing

BizLink adheres to strict quality control checks that are performed at all stages in the production process. In addition, the company’s entire range of products are ISO 9001:2015 and ISO 14001:2015 approved, and are 100 percent electrically tested for functional and safety-related parameters, and comply with all applicable national and international standards.

International Approvals

BizLink's vast product portfolio of plugs, connectors, and bulk cables are approved by a wide range of National Certification Bodies (NCB) from around the world, including Australia, Japan, and the U.S.A. We also supply plugs for countries in which NCB-approval is not mandatory (Figure 4).

Environmental Standards

With the growing push in several countries to ban phthalates and PAHs as they relate to the framework of RoHS II and similar approaches, BizLink has prioritized creating clean, sustainable products that reduce the risk of environmental impact. As a result of this initiative, the company has developed a range of halogen-free products, which do not contain halogens – chlorine (CI), bromine (Br), fluorine (F), iodine (I), and astatine (At), and have characteristics that are similar to PVC.In compliance with EN 50525-3-11 standards, these halogen-free cable products deliver several benefits and key features including:

- No evidence of cross-linked material and thus, better recyclability

- Timely implementation of imminent legal requirements

- Solutions for static and various dynamic application

- Thorough technical support in designing customized product lines